Machine tool coolant supply

Medium and High Pressure Pumps

The requirements for the supply of filtered, lubricating coolants (i.e. water-soluble coolants and oils) to machine tools vary to a large degree. They require different pump solutions: small and compact pumps for external cooling, centrifugal pumps with closed impellers for medium pressure applications (up to 50 bar) or high pressure pumps (up to 200 bar) based on screw spindle technology for internally cooled tools. The pumps must either be designed exactly for a specific working point or controlled by a variable frequency drive.

For 50 Hz applications please refer to the product lines on the European website:

European products

Pumps selection menu

Here you can easily find the right pump for your machine tool

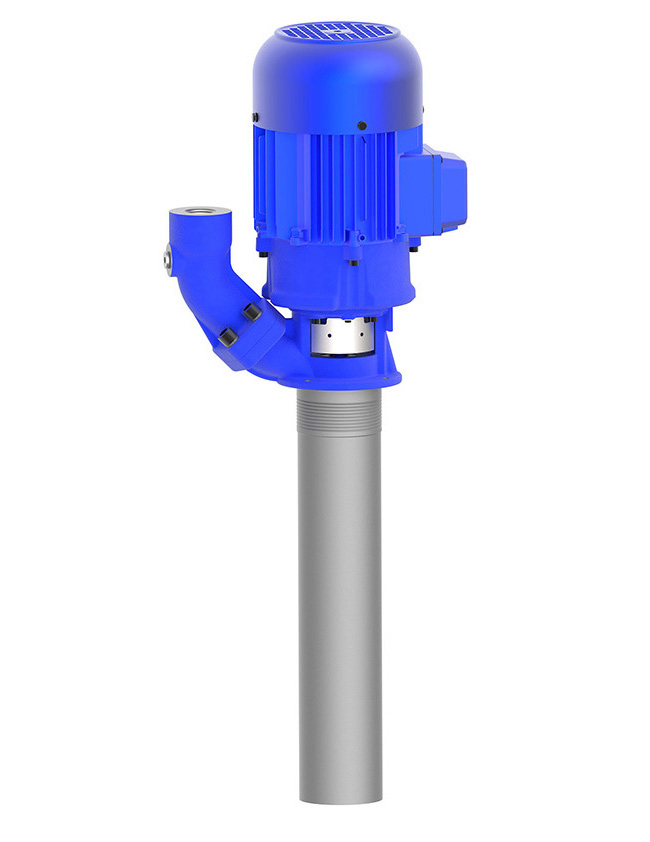

Immersion Pumps

TS

| Impellers | peripheral |

| Fluids | coolants, emulsions, oils |

| Volumetric delivery | up to 20 GPM |

| Delivery head | up to 290 Feet |

Examples of applications

-

In shallow tanks or chip conveyors

-

Spray pistol

-

Externally cooled tools or CTS application

-

Medium pressure range

Immersion Pump

-

Easy mounting on top of the tank

-

Compact design

-

Short immersion depths

-

Special execution for tempering units available

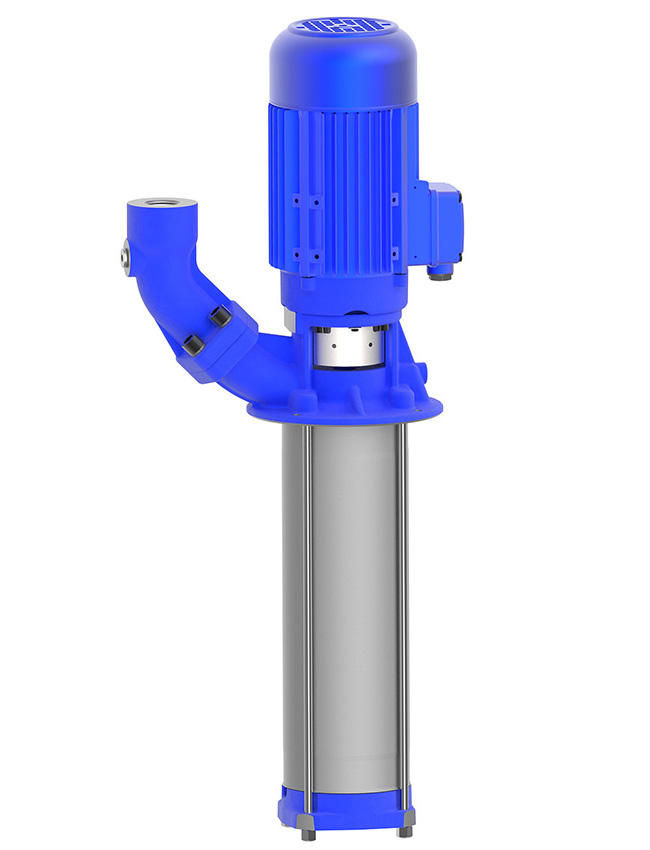

Immersion Pumps

(S)TC

| Impellers | closed |

| Fluids | coolants, emulsions, oils |

| Volumetric delivery | up to 600 l/min |

| Delivery head | up to 225 m |

Examples of applications

-

Externally cooled tools or CTS application

-

Grinding applications

-

Medium pressure range

Immersion Pump

-

Easy mounting on top of the tank

-

Simple piping connection with optional SAE flange

-

Closed impellers provide optimal hydraulic efficiencies while minimizing power consumption

-

Pump performance curves can be regulated using an adapted frequency converter

Immersion Pumps

(S)TH | STH

| Impellers | closed |

| Fluids | coolants, emulsions, oils |

| Volumetric delivery | up to 410 GPM |

| Delivery head | up to 850 Feet |

Examples of applications

-

Externally cooled tools or CTS application

-

Pump performance can be adapted to a certain working point

-

Central coolant system

Immersion Pump

-

Easy mounting on top of the tank

-

Simple piping connection with optional SAE flange

-

Closed impellers provide optimal hydraulic efficiencies while minimizing power consumption

-

Pump performance curves can be regulated using an adapted frequency converter

-

Grinding version available

-

An even wider range of performance curves

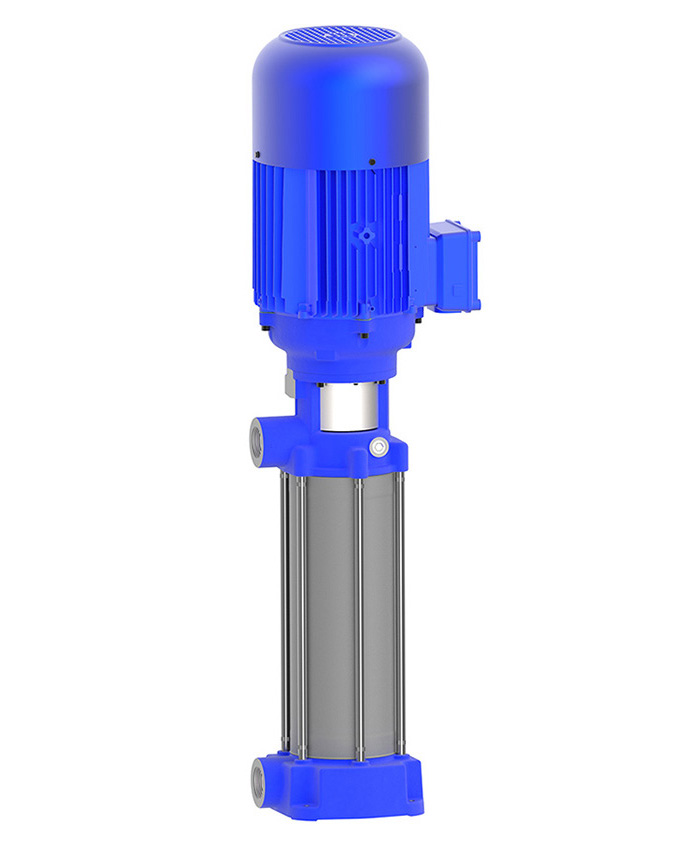

Pressure Boosting Pumps

FH

| Impellers | closed |

| Fluids | coolants, emulsions, oils |

| Volumetric delivery | up to 160 GPM |

| Delivery head | up to 850 Feet |

Examples of applications

-

Externally cooled tools or CTS application -

Pressure boosting systems

-

Pressure boosting at the machine (within central coolant systems)

Pressure Boosting Pump

-

Foot mounted inline pumps; gravity fed

-

Closed impellers provide optimal hydraulic efficiencies while minimizing power consumption

-

Pump performance curves can be regulated using an adapted frequency converter

-

An even wider range of performance curves

-

As a booster pump for inlet pressures of up to 26 bar

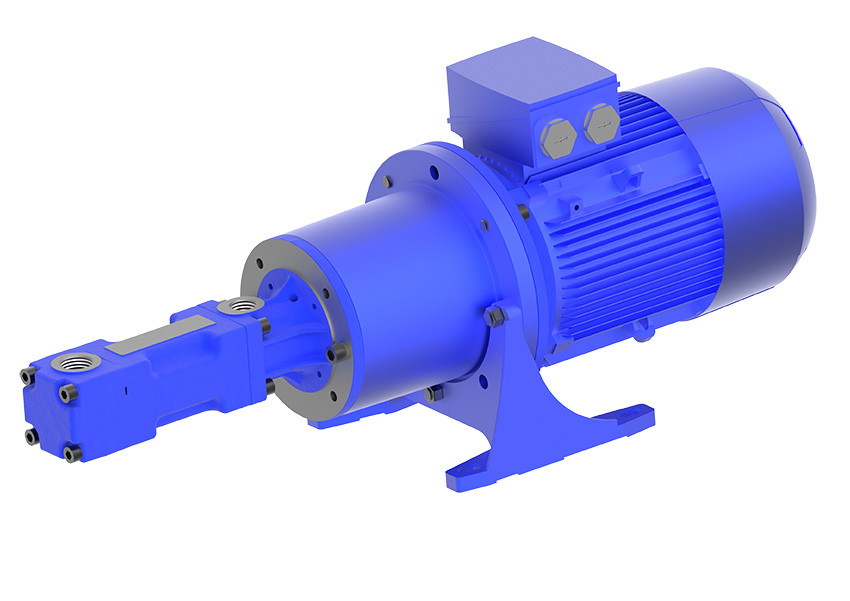

Screw Spindle Pumps

BFS | TFS

| Spindles | hardened, precision ground |

| Fluids | coolants, emulsions, oils |

| Volumetric delivery | up to 232 GPM |

| Delivery pressure | up to 2175 PSI |

Examples of applications

-

High pressure applications, such as, grinding or deep hole drilling

-

Central coolant system

-

Demand based pump regulation with frequency converter (VFD)

Screw Spindle Pump / High Pressure Pump, Immersion Style

-

Highly wear-resistant silicon carbide housings and specially hardened spindles

-

Excellent efficiencies

-

6 sizes for optimum operating point selection

-

Available fully assembled with mounting plate, valve and piping

-

Available with adapted frequency converter for optimum adaptation to the operating point

-

Energy efficient solution in combination with the Brinkmann Pumps Offset regulation while at the same time minimizing pressure peaks during tool changes

Screw Spindle Pumps

FFS

| Spindles | hardened, precision ground |

| Fluids | coolants, emulsions, oils |

| Volumetric delivery | up to 232 GPM |

| Delivery pressure | up to 2175 PSI |

Examples of applications

-

High pressure applications, such as, grinding or deep hole drilling

-

Central coolant system

-

Demand based pump regulation with frequency converter (VFD)

Screw Spindle Pump, High Pressure Pump, Inline Style

-

Highly wear-resistant silicon carbide housings and specially hardened spindles

-

Excellent efficiencies

-

6 sizes for optimum operating point selection

-

Available fully assembled with mounting plate, valve and piping

-

Available with adapted frequency converter for optimum adaptation to the operating point

-

Energy efficient solution in combination with the Brinkmann Pumps Offset regulation while at the same time minimizing pressure peaks during tool changes

![[Translate to US - english:] #background](/fileadmin/user_upload/brinkmann_Teaser_Hochdruckpumpe_volleBreite.jpg)