60 Hz

Screw Spindle Pumps BFS2

Screw Spindle Pumps

Screw spindle pumps with their silicon carbide spindle housing and highly wear resistant spindles are capable of achieving extremely high pressures.

Brinkmann high pressure screw pumps are designed for pumping filtered and lubricating fluids such as coolant oils and watersoluble coolants.

High pressure screw pumps are NOT designed for dry-running.

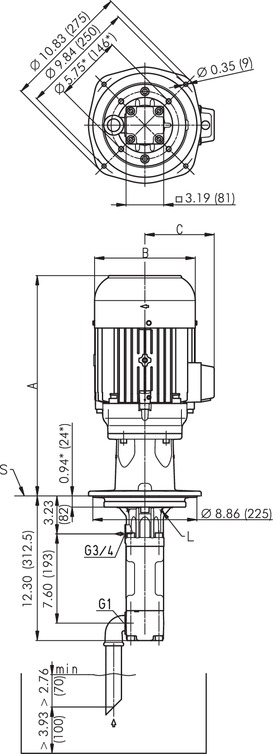

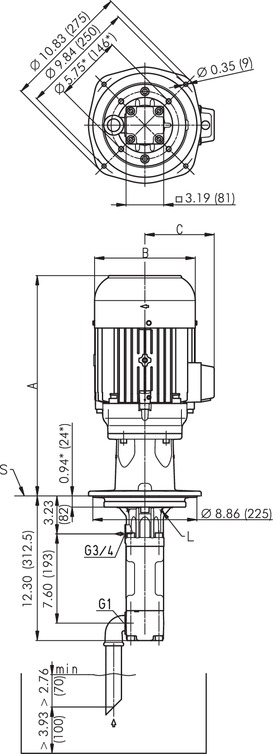

Technical drawing

Screw Spindle Pumps - BFS2

*) Dimensions for 4-pole standard

motor upon request

L = Leakage hole

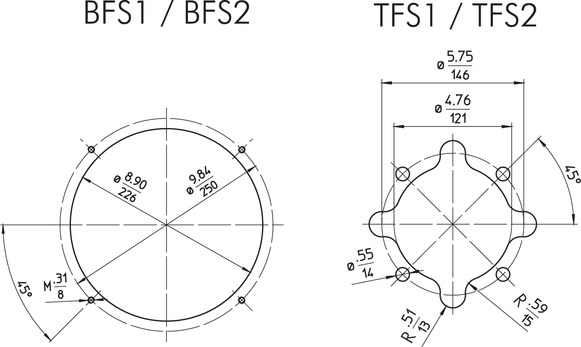

S = Mounting plate, please refer to

the cut-out of mounting hole

Dimensions in Inches / mm

All corners must be deburred!

According to ISO 2768-m

| Power 2-poles | A | B | C |

| HP | Inch | Inch | Inch |

| B 2 / 2.3 | 16.34 | 6.93 | 5.12 |

| B 2.6 | 17.36 | 6.93 | 5.12 |

| B 2.9 / 3.4 / 3.9 | 18.66 | 6.93 | 5.12 |

| B 4.6 / 5.1 / 6.1 | 20.20 | 8.58 | 5.91 |

| B 7.7 / 8.4 | 21.38 | 8.58 | 5.91 |

| B 9.2 / 10 | 22.99 | 10.16 | 7.60 |

| B 11.5 / 13.8 | 24.49 | 10.16 | 7.60 |

| B 16.9 / 20.1 | 24.80 | 12.20 | 9.45 |

Applications

| Types of fluid | coolants cooling/cutting oils Oils |

| Kinematic viscosity | 4.6...200 SSU (1...45 mm²/s) higher viscosity upon request |

| Max. air content | 3 - 5 vol. % |

| Pumping temperature | max. 140 °F (60° C) higher temperatures upon request |

| Recommended filtration levels | General Machining (Turning, milling, drilling) < 50 µm Grinding and machining of aluminum < 20 µm For additional information please refer to mechanical features within the technical information section. |

Construction

| Pressure and | Cast iron |

| Spindle Housing | Silicon Carbide, one-piece, highly wear resistant and precision |

| Screw spindles | Hardened tool steel specially treated, alloy; highly wear resistant and precision ground |

| Gasket | Viton ® |