Your problem solver and system developer in one

Competence

BRINKMANN PUMPS has expertise at the highest level! We provide a comprehensive understanding of the pump technology used on site. In short, we know what we are talking about.

We take a wide approach towards effective coolant management and in doing so, we're always looking at the bigger picture. For you as a manufacturer or a system developer, this means that we can realize solutions together, at any time. Use our creative potential, we think for you systematically.

Regardless of whether you produce machine tools or use them yourself...whether you develop systems for the print industry or beverage production...or whether your technology ensures industrial tempering and cooling. We often have a suitable solution at hand. Get in touch with us!

Your productivity is our focus

Engineering

BRINKMANN PUMPS makes the entire range of coolant pumps available to you. In each case, the application-specific and customer oriented solution takes center stage. In addition, a well thought-out modular design system enables implementation that is technically highly sophisticated as well as very economical.

At BRINKMANN, the development of customer oriented solutions is targeted from the beginning. The engineering department builds upon the precise knowledge of the different pump technologies, electric motor manufacturing, the fluids and last but not least, the expertise associated with the application. In addition, essential knowledge surrounding the characteristics of all of the materials that are used forms the basis of each product solution.

As a direct consequence of the constantly changing requirements of our international clients, our highly qualified team of developers (consisting of engineers and manufacturing specialists) prepare innovative and market-driven approaches to solutions. Then, in the development phase, each product has to prove itself on highly sophisticated testing equipment as well as in intensive continuous duty tests. Immediately after approval has been given, serial production starts within a short period of time. Why do we do this? So that when applied, everything runs smoothly and you can use your system productively as soon as possible.

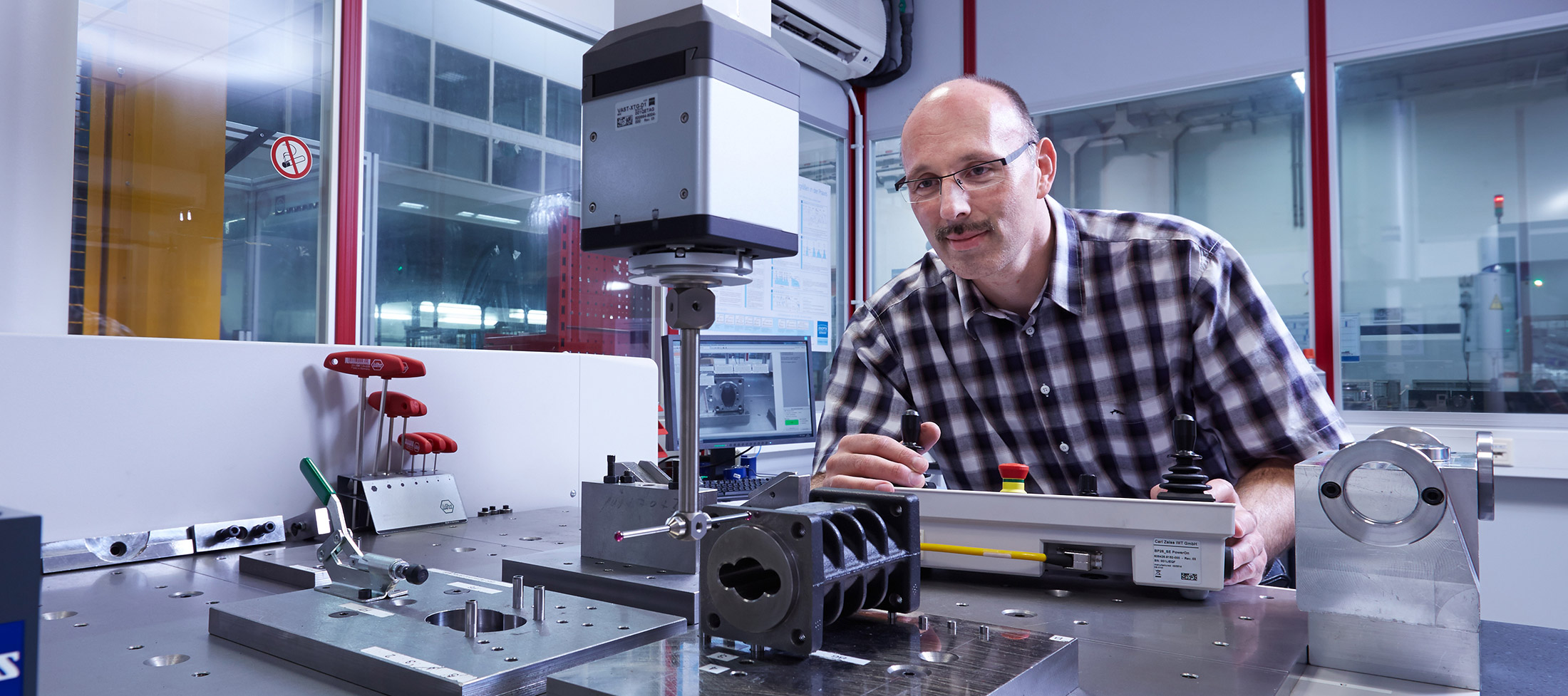

Quality at the highest level

Quality

Quality can be planned in advance, tested and implemented. This is why all phases of the production process are monitored using the latest measurement techniques. Furthermore, the team has trained specialists who monitor all relevant manufacturing parameters. BRINKMANN PUMPS is certified in accordance with quality management system EN ISO 9001. This testifies to the strict, demanding approach to quality which implemented in all departments throughout the company.

Whether it is the selection of suppliers and materials or the continuous monitoring of production, at BRINKMANN, our own high quality requirements are reflected in the permanent monitoring of all ongoing processes and it also encompasses the strict monitoring of shipments and logistics.

This is why independent certification in accordance with ISO 9001 is a must. Applying the latest measurement and testing methods, and with an eye on the continuous improvement of manufacturing (in all phases of production), our motivated team embraces this approach to quality every day.

![[Translate to US - english:] Stage Image](/fileadmin/user_upload/header_unternehmen_profil_2200px.jpg)