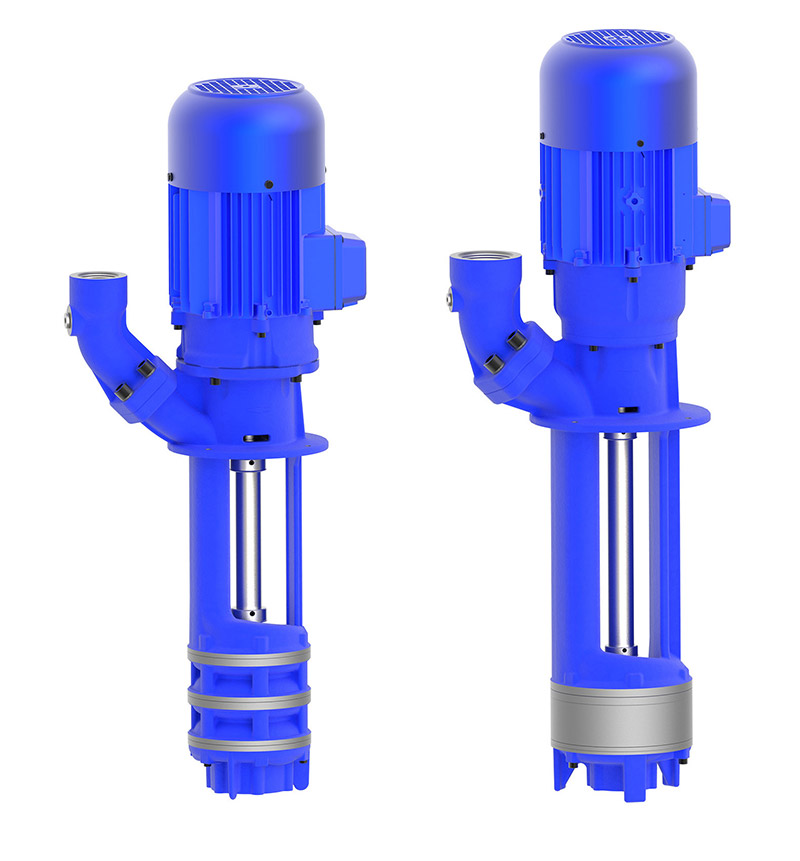

Quick Suctioning Immersion Pumps

SAL | SGL

Quick Suctioning Immersion Pump

-

Easy mounting on top of the tank

-

Simple pipe connection with 45 degree SAE flange

-

Long lifetime due to low wear anti-friction bearing

-

Patented BRINKMANN´s Suction De-aeration System

-

Multi-stage version (steep performance curves)

-

Immersion depth up to 1.5 m possible

-

Available with additional agitator at the pump suction for breaking up clusters of grinding sludge

| Item group | Pump type | Capacity |

Head |

|||||||

|

|

Quick Suctioning Immersion Pumps | 165 GPM | ...56 Feet | ||||||

|

|

Quick Suctioning Immersion Pumps | 80 GPM | ...250 Feet | ||||||

|

|

Quick Suctioning Immersion Pumps | 122 GPM | ...260 Feet | ||||||

|

|

Quick Suctioning Immersion Pumps | 180 GPM | ...330 Feet | ||||||

|

|

Quick Suctioning Immersion Pumps | 630 GPM | ...180 Feet | ||||||

|

|

Quick Suctioning Immersion Pumps | 320 GPM | ...300 Feet | ||||||

|

|

Quick Suctioning Immersion Pumps | 400 GPM | ...425 Feet | ||||||

|

|

Quick Suctioning Immersion Pumps | 450 GPM | ...210 Feet | ||||||

|

|

Quick Suctioning Immersion Pumps | 700 GPM | ...300 Feet | ||||||

|

|

Quick Suctioning Immersion Pumps | 90 GPM | ...120 Feet | ||||||

|

|

Quick Suctioning Immersion Pumps | 120 GPM | ...130 Feet | ||||||

|

|

Quick Suctioning Immersion Pumps | 220 GPM | ...320 Feet | ||||||

|

|

Quick Suctioning Immersion Pumps | 350 GPM | ...240 Feet | ||||||

|

|

Quick Suctioning Immersion Pumps | 650 GPM | ...345 Feet |