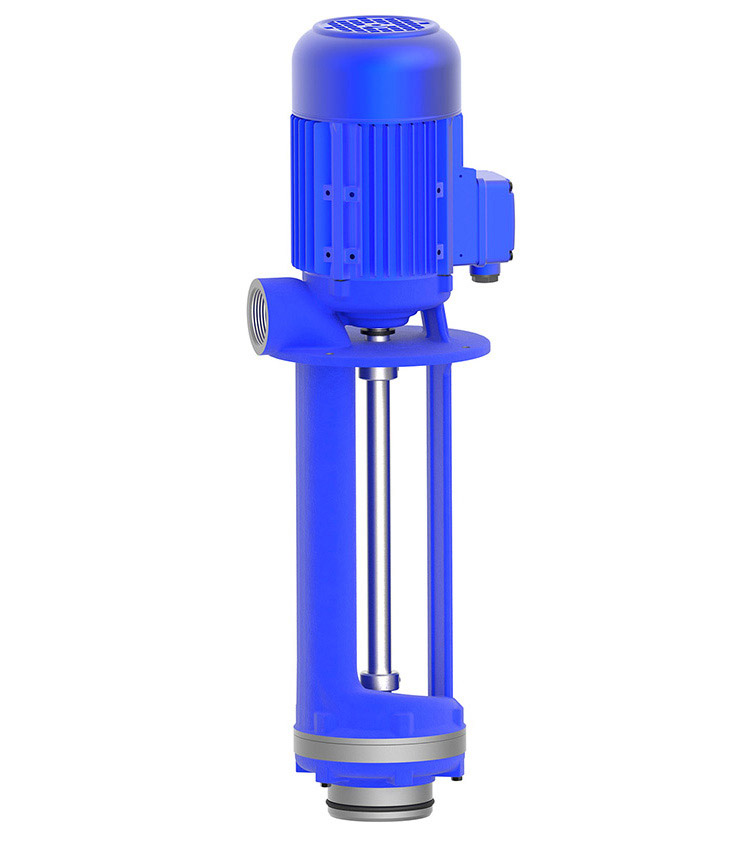

Suction Immersion Pumps

TAS | STS

Suction Pump

-

Easy mounting on top of the tank

-

Simple pipe connection with 45 degree SAE flange

-

Long lifetime due to low wear anti-friction bearing

-

Simple connection on the suction side

-

Multi-stage version

| Item group | Pump type | Capacity |

Head |

|||||||

|

|

Suction Immersion Pumps | 600 GPM | ...150 Feet |