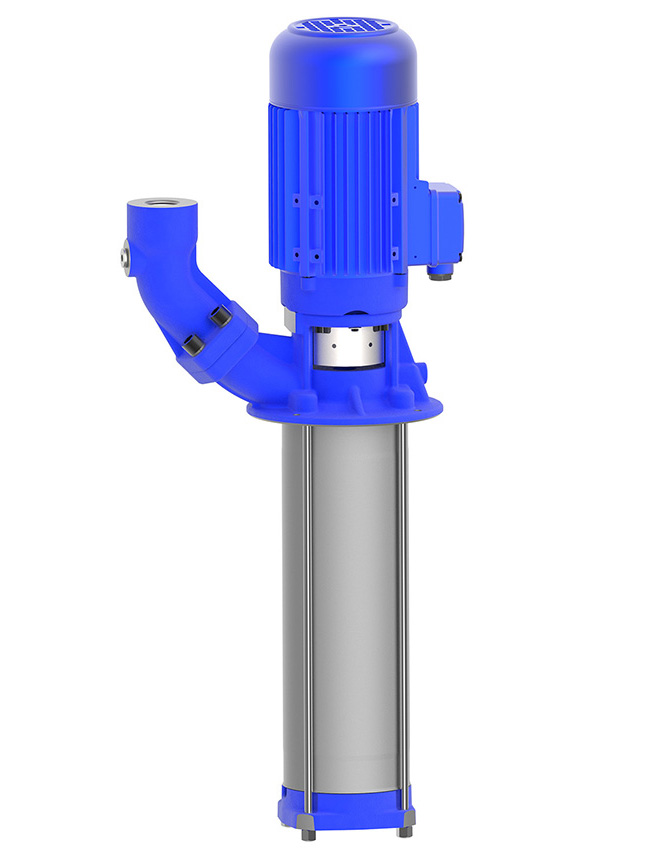

Immersion Pumps

(S)TH | STH

Immersion Pump

-

Easy mounting on top of the tank

-

Simple piping connection with optional SAE flange

-

Closed impellers provide optimal hydraulic efficiencies while minimizing power consumption

-

Pump performance curves can be regulated using an adapted frequency converter

-

Grinding version available

-

An even wider range of performance curves

| Item group | Pump type | Capacity |

Head |

|||||||

|

|

Immersion Pumps | 12.4 GPM | ...880 Feet | ||||||

|

|

Immersion Pumps | 23 GPM | ...840 Feet | ||||||

|

|

Immersion Pumps | 44 GPM | ...850 Feet | ||||||

|

|

Immersion Pumps | 75 GPM | ...800 Feet | ||||||

|

|

Immersion Pumps | 128 GPM | ...800 Feet | ||||||

|

|

Immersion Pumps | 150 GPM | ...780 Feet | ||||||

|

|

Immersion Pumps | 320 GPM | ...620 Feet | ||||||

|

|

Immersion Pumps | 410 GPM | ...420 Feet |